The advantage of the Pease Model Twenty Two? It was an early reliable “continuous feed” machine. The user could image sheet after sheet on a roll of sensitized paper and the finished prints would be wound dry on a roll to be cut apart — much more efficient than cut sheet feed.

A true blueprint this machine produced was wet developed and had to be carried across a heat source to dry before they were rolled up. The process had to be well-timed for development, rinsing and drying. Alkaline chemicals that washed off the prints were drained right into the print shop floor drains.

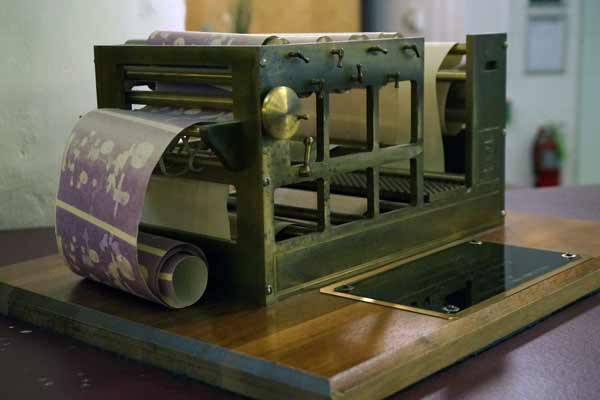

This is a scale brass replica of the Pease Model Twenty Two machine; it resides on the reception desk at Cushing — it was milled by employees for Cathie and Joe’s grandfather and presented at the company’s 50th anniversary celebration.

The original advertisement referenced above most likely appeared in the The Blueprinter, which was an industry magazine circulated to customers.

Check out images of past issues. Cushing would also insert these sorts of tear sheets into select jobs and distribute them at local events such as the Engineers Club.

Browse an array of architectural printing services.

Or explore managed print services and printer rentals.

Questions or need an estimate?

Follow Us